re:suede

The backstory

In 2012, we launched InCycle: a closed-loop collection which included a shoe designed for composting. Unfortunately, the infrastructure and demand wasn’t quite there, so it never took off. Since then we've worked hard to address the learnings. During this time we also noticed a positive shift in consumer behaviours. Conversations around circularity were gaining momentum, and consumer desires for better fashion choices were growing. Almost a decade later, we picked up where we left off. And in 2021, the RE:SUEDE experiment was born.

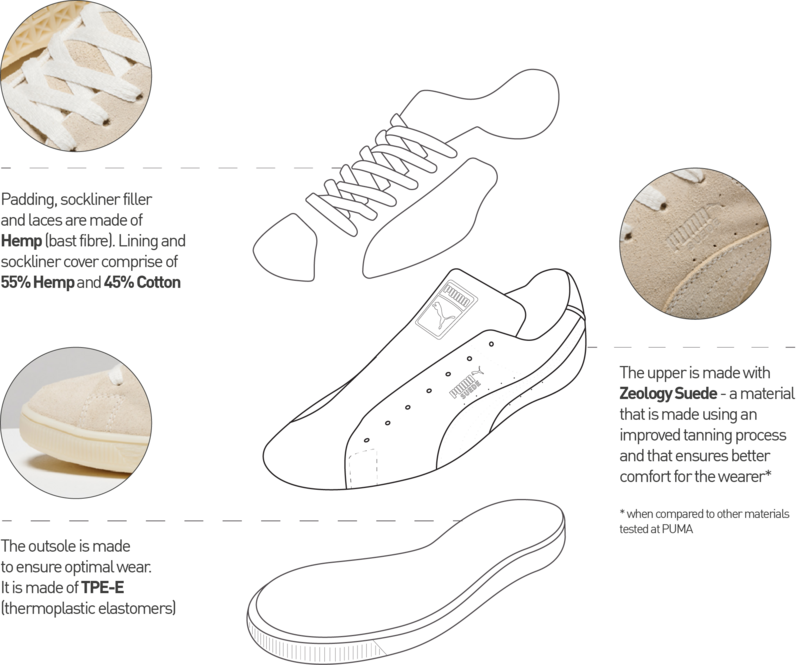

Redesigning an icon

Knowing the demand was there, our first challenge was to make a stylish and comfortable shoe that people would want to wear. What better candidate than our original footwear legend, the Suede. The RE:SUEDE reimagines this icon, from the upper to the sole, lining and laces: every element has been designed and carefully chosen for comfort and their potential to decompose.

Consumer Testing

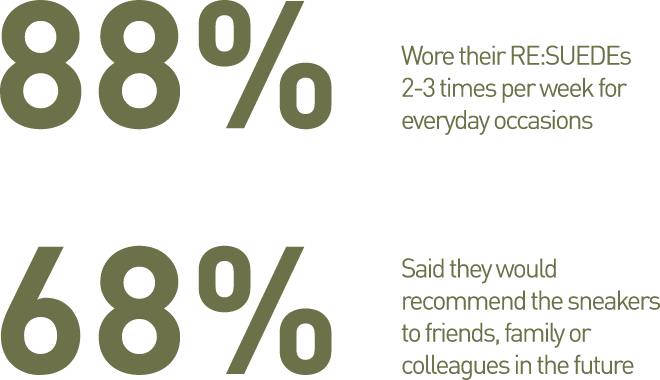

In 2022, 500 participants were asked to wear and love their RE:SUEDEs for six months before returning them to PUMA for the next stage of the experiment. A total of 412 pairs of worn RE:SUEDEs were returned to PUMA and sent to our industrial composting partner Valor Composting - a family business that takes a different approach to waste.

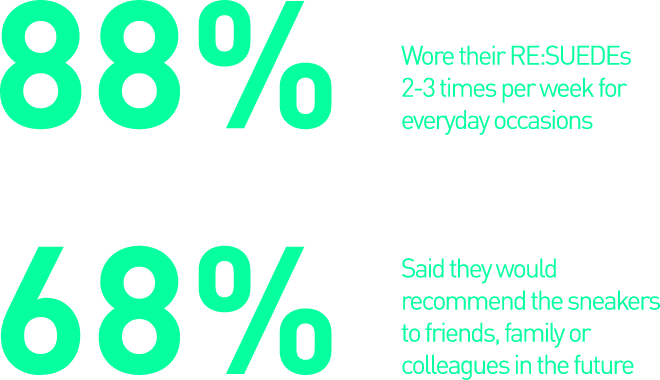

Overall, people who took part in the experiment enjoyed wearing their RE:SUEDEs:

Turning our RE:SUEDES into compost

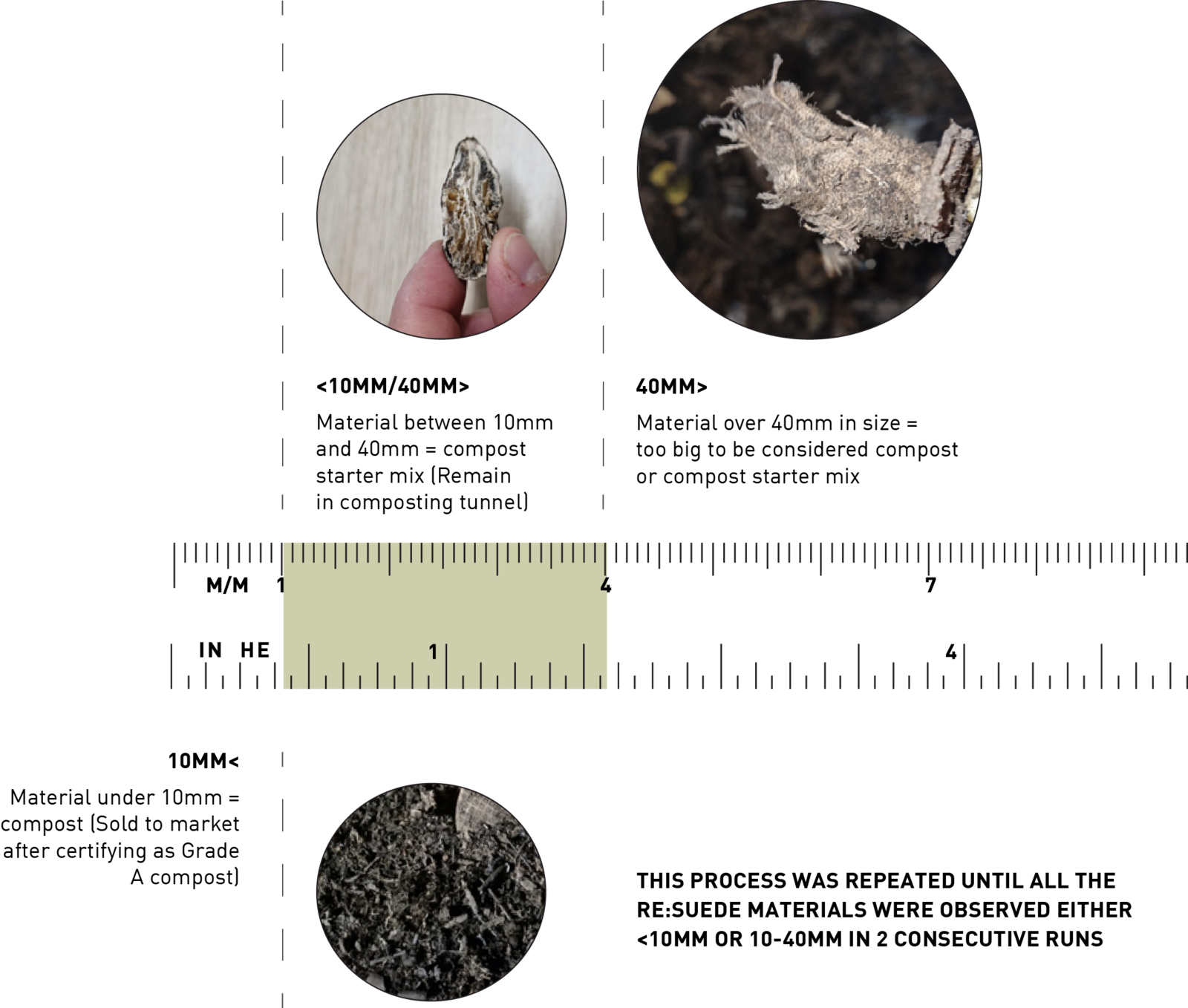

At Valor Composting the shoes went through an industrial composting process. The RE:SUEDEs were shredded and mixed with other green household waste and placed into a composting tunnel. Every 10-14 days the contents of the tunnel were sieved to see how small the pieces of RE:SUEDE had become. This process was repeated until all the RE:SUEDE materials were observed as either <10MM OR 10-40MM in size.

What we discovered

After approximately 2.5 months, the majority of the RE:SUEDEs had broken into pieces small enough for compost (<10mm) or compost starter mix (10-40mm). The compost was tested and confirmed as Grade A compost under the Netherland standard applicable to Ortessa, was sold on and is somewhere in the Dutch landscape right now.

Where we’ve landed

We discovered that it is possible to turn the RE:SUEDE into Grade A compost under specific industrial conditions provided by Ortessa. That’s a win. However, the soles slow the process down, resulting in more composting cycles required to turn the shoe into Grade A compost, meaning they can’t be processed using today’s standard industrial composting operating procedures. But with a new business model in composting, and a higher volume of input into it, those standard operating procedures can change.

What‘s next

RE:SUEDE has given us a lot to learn from and build on. The experiment proved that there is an appetite and future for RE:SUEDE. However, to get there, we need more scale. We will continue to innovate with our partners to determine the infrastructure and technologies needed to make the process viable for a commercial version of the RE:SUEDE, including a takeback scheme, in 2024.

Explore more

We believe that being open and transparent about our efforts and actions – is the only way we’ll see results. That’s why we made a detailed report to provide a transparent look at the RE:SUEDE experiment.

Related News

FAQ

Want to know more?

A PUMA experiment in circularity. RE:SUEDE is an experimental version of the iconic Suede sneaker.

Materials are sourced from Italy, China, Thailand and Vietnam. The RE:SUEDE sneakers are stitched and assembled in Romania.

Find all the details in this handbook.

Yes. A limited number of RE:SUEDEs are now available for purchase in our online store. Click here to buy your RE:SUEDES.

PUMA takes responsibility for helping create a better future for all. This includes its products and their afterlife.

No. The RE:SUEDE experiment used materials that decompose under tailor-made controlled, industrial composting conditions.

The compost from the process measuring (<10mm) certified as Grade A compost under the Netherland standard applicable to Ortessa was sold on and is somewhere in the Dutch landscape right now.

Grade A compost (the highest certification from Keurcompost in the Netherlands) can be used in agriculture and horticulture.

Corporate Sustainability

Explore PUMA's Corporate Sustainability Reports, Codes, Policies, Handbooks and more.

Sustainability Report

We provide annual sustainability reports within our annual reports. Explore them here.